Nicotine Pouches Brands: A Comprehensive Guide to Industry Trends, Manufacturing, and Supplier Selection

1. Industry Background and Trends

Nicotine pouches—also known as nic bags—are redefining the tobacco-free segment with their clean-label appeal and discreet usage format. Global demand is surging, with a projected CAGR of 25% through 2028, fueled by growing awareness of smoking alternatives and tightening regulations on combustible tobacco.

This boom has created a dynamic landscape where brand identity, product innovation, and manufacturing quality are key differentiators. While household names like ZYN and VELO dominate retail, increasing numbers of wholesalers and retailers are turning to OEM and white-label nicotine pouch solutions to compete on both price and customization.

For international buyers, selecting the right nicotine pouch brand is no longer just about flavor—it’s about compliance, technology, and long-term supplier reliability.

2. Production Process of Nicotine Pouches

Understanding the underlying nicotine bag manufacturing process is critical for assessing brand and supplier capabilities. Though most production follows a similar framework, execution quality varies significantly:

a. Nicotine Sourcing and Refinement

Manufacturers may use either tobacco-derived or synthetic nicotine. Top-tier facilities opt for USP-grade nicotine to ensure purity, safety, and cross-border compliance.

b. Formulation and Blending

Nicotine is mixed with carriers (usually plant fibers) and infused with flavoring. Differences in formula complexity, moisture control, and sensory performance define the user experience—and distinguish leading brands.

c. Pouch Assembly and Packaging

Precision filling machines determine consistency in weight, texture, and nicotine dosage. Automation and hygienic packaging are essential for scalability and quality assurance.

d. Quality Control Protocols

Manufacturers like Snuff Factory apply robust quality checks—from lab testing for chemical stability to physical verification for uniformity. Brands lacking proper QC risk product recalls and regulatory pushback.

Buyers serious about performance, safety, and regulatory fit should always conduct due diligence on a manufacturer’s production line, especially if planning bulk orders or OEM cooperation.

3. Brand, Origin, Equipment, and Technology Differences

Not all nicotine pouch brands are created equal. Key points of differentiation include:

a. Brand Tier and Target Market

Premium retail brands (e.g., ZYN, VELO) serve general consumers, but are not always suitable for B2B buyers looking to build private labels. In contrast, OEM-ready manufacturers like Snuff Factory cater directly to wholesalers, offering private formulas, flexible packaging, and fast turnaround.

b. Geographic Origin

-

Sweden & the US: Known for high-quality, regulation-driven production—ideal for retail or pharma-grade products.

-

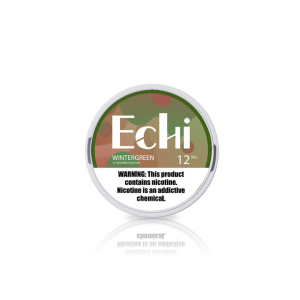

China: Offers significant cost advantages with mass production capability. Modern facilities (e.g., Echi’s Shenzhen factory) increasingly meet EU/US safety standards.

-

Europe: Emphasis on synthetic nicotine, eco-conscious sourcing, and smaller batch flexibility.

c. Equipment and Automation

Factories equipped with high-speed pouching lines, humidity control systems, and digital QC modules offer more consistent output. This matters in both large-volume supply and brand perception.

d. Certifications and Compliance

ISO 9001, GMP, and SGS chemical reports are common indicators of a qualified supplier. Ensure your chosen partner offers full documentation for export, customs, and regulatory review.

4. How to Choose a Reliable Supplier (Echi Nicotine Bag Manufacturer)

Whether you’re building a nicotine brand or sourcing for distribution, choosing the right nicotine pouch manufacturer can determine your product’s success. Key selection steps include:

a. Evaluate Industry Experience

Look for partners with a clear portfolio in nicotine bag OEM or white-label manufacturing. Suppliers like Echi/Snuff Factory offer proven experience across multiple regions and formats.

b. Assess Capacity and Lead Time

Can the factory scale with your growth? Do they maintain consistent turnaround even during peak seasons?

c. Check Regulatory Readiness

Confirm that your supplier can meet U.S. FDA, EU TPD, or local market requirements depending on your distribution zone.

d. Flavor and Design Flexibility

Customization drives consumer loyalty. Ask whether the supplier supports proprietary flavor formulas, pouch sizes (e.g., slim, standard), and market-specific packaging designs.

e. Case Studies and Reputation

Request testimonials or examples of successful white-label collaborations. Transparent factories will gladly provide references, product catalogs, or sample batches.

To explore a vetted production partnership, contact Snuff Factory or review their product solutions here.

5. Final Suggestions

For global B2B buyers, entering or expanding in the nicotine pouch sector requires more than just following brand trends—it demands sourcing strategy and a forward-thinking supplier network. Here’s what to keep in mind:

-

Avoid Dependency on One Brand: Even top brands face supply risks or pricing instability. White-label options provide agility without compromising quality.

-

Prioritize Transparency: Choose suppliers who offer full ingredient traceability, test reports, and compliance support—especially if operating across multiple markets.

-

Think Long-Term: The right supplier grows with you. Seek out manufacturing partners like Snuff Factory that offer both entry-level and advanced OEM services.

Bottom Line:

Success in the nicotine pouch market is driven by informed sourcing decisions. Partnering with a trusted, compliant, and flexible nicotine bag manufacturer gives your brand the edge in pricing, customization, and customer trust.

Start your journey with Snuff Factory to explore scalable nicotine pouch manufacturing solutions tailored to your business.

Leave a Reply

Want to join the discussion?Feel free to contribute!