Nicotine Pouches Brands: A Comprehensive Guide to Industry Trends, Manufacturing, and Supplier Selection

1. Industry Background and Trends

Nicotine pouches—also known as nic bags—have rapidly evolved from niche alternatives to mainstream nicotine delivery systems. Driven by a growing global preference for smoke-free, discreet, and health-conscious consumption, this segment is forecasted to grow at a compound annual growth rate (CAGR) exceeding 25% through 2028.

Leading brands in this space, including both consumer-facing names and OEM suppliers, are innovating across flavor development, pouch composition, and regulatory adaptability. With global consumers demanding variety, clean labeling, and high quality, nicotine pouch producers are shifting toward white-label and custom OEM manufacturing to support retail chains, e-commerce players, and health-focused distributors.

For international buyers, staying competitive means selecting reliable nicotine pouch manufacturers who can deliver consistency, compliance, and customization at scale.

2. Production Process of Nicotine Pouches

Understanding how nicotine pouches are made helps B2B buyers evaluate production capabilities and brand positioning. Most modern pouch brands share a similar four-stage process, though quality and technology vary significantly.

a. Sourcing and Refining Nicotine

High-purity nicotine is either extracted from tobacco plants or synthetically produced. Top-tier suppliers focus on pharmaceutical-grade nicotine, which ensures regulatory compliance in markets like the EU, U.S., and Australia.

b. Formulation and Blending

Nicotine is combined with plant-based carriers like cellulose and infused with flavoring. Brands differentiate through flavor complexity, mouthfeel, and nicotine concentration (commonly ranging from 3mg to 12mg per pouch).

c. Precision Pouching and Sealing

Automated machinery ensures uniform pouch weight, size, and nicotine dispersion. In high-output facilities like those operated by Snuff Factory, automated processes guarantee scalability and minimize batch variation.

d. Quality Assurance

Final products undergo stability tests, microbiological assessments, and nicotine content validation. Certifications such as ISO or GMP are indicators of manufacturing excellence.

Choosing a manufacturer transparent about its nicotine bag manufacturing process is essential for ensuring product safety, marketability, and brand reputation.

3. Brand, Origin, Equipment, and Technology Differences

While flavor variety and brand design are visible to end-users, behind-the-scenes variables like geographic origin and production technology often determine product performance and cost.

a. Brand Positioning

Global leaders like VELO, ZYN, and On! have set high standards for nicotine pouches. However, OEM brands and white-label manufacturers now offer private-label solutions with similar quality levels—giving distributors a competitive edge with custom branding.

b. Country of Origin

-

Sweden: Renowned for its heritage in snus and nicotine pouches, with strict regulatory controls and advanced equipment.

-

USA: Focuses on pharma-grade ingredients and stringent FDA oversight, often resulting in higher production costs.

-

China: Offers cost-efficiency and high production capacity, ideal for large-volume white-label projects—if paired with strong quality assurance protocols.

c. Technology Investment

Factories with modern pouching systems produce more uniform products. Snuff Factory, for example, utilizes automated, high-speed production lines to meet international scale and quality demands.

d. Certifications and Safety Standards

Check for ISO 9001, ISO 22000, SGS testing, and EU/TPD compliance when reviewing supplier qualifications.

For buyers seeking both flexibility and dependability, Snuff Factory stands out for its combined expertise in OEM and white-label pouch manufacturing.

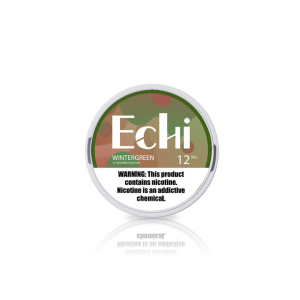

4. How to Choose a Reliable Supplier (Echi Nicotine Bag Manufacturer)

Sourcing the right partner is critical. Here’s how to evaluate nicotine pouch manufacturers effectively:

a. Verify Industry Experience

Work with factories that have a proven track record in nicotine bag manufacturing, particularly those offering B2B private-label and bulk services, like Snuff Factory.

b. Check Production Capacity

Ensure your supplier can scale alongside your business. Ask about monthly output, equipment specs, and expansion readiness.

c. Demand Documentation

Request COAs (Certificate of Analysis), MSDS (Material Safety Data Sheets), and regulatory certifications such as ISO, GMP, and TPD compliance.

d. Prioritize Customization

Your market positioning relies on product uniqueness. Confirm whether the manufacturer supports customized:

-

Nicotine strengths

-

Flavor profiles

-

Pouch fabric and sizing

-

Branded or unbranded packaging

e. Review References or Case Studies

Established manufacturers should be able to provide success stories or references. Brands like Snuff Factory maintain transparency and long-term client partnerships.

👉 Contact Snuff Factory for detailed production capabilities and sample requests: Get in Touch

5. Final Suggestions

For international buyers and private-label brands, the nicotine pouch market offers both growth potential and complexity. A few final recommendations:

-

Select Manufacturer Over Brand: OEM and white-label suppliers offer greater flexibility and margin control than simply distributing an existing retail brand.

-

Prioritize Transparency: A supplier willing to share their full production process, testing protocols, and compliance documents is likely to be a trustworthy partner.

-

Stay Ahead of Trends: Monitor regulation (TPD, FDA), ingredient bans, and consumer flavor trends to ensure your product line remains viable long-term.

-

Invest in Long-Term Partnerships: Consistency in formulation, supply chain, and packaging is only possible when working with stable, well-equipped manufacturers.

For businesses looking to launch or expand their nicotine pouch offerings, strategic partnerships with established manufacturers like Snuff Factory provide a strong foundation for market success.

Conclusion:

Choosing the right nicotine pouch brand starts with selecting the right manufacturer. Whether you’re building your own label or sourcing in bulk, understanding the production process, supplier credibility, and market trends gives you the leverage needed to succeed. Invest wisely, and let your nicotine pouch brand stand out with quality, compliance, and competitive edge.

Leave a Reply

Want to join the discussion?Feel free to contribute!