Nicotine Pouches Brands: A Comprehensive Guide to Industry Trends, Manufacturing, and Supplier Selection

1. Industry Background and Trends

As demand grows for cleaner, smoke-free alternatives to traditional tobacco, nicotine pouches have surged in popularity across Europe, North America, and Asia. Known for their discreet, tobacco-free format, these pouches—also called nic bags—offer a compelling solution for modern consumers seeking convenience and reduced health risks.

The global nicotine pouch market is projected to grow at a CAGR of 25% through 2028. Brands and distributors are increasingly turning to white-label nicotine bag solutions and partnering with trusted OEM manufacturers to stay competitive. These partnerships enable product diversification, ensure regulatory compliance, and accelerate go-to-market timelines.

2. Production Process of Nicotine Pouches

The key to differentiating among nicotine pouch brands lies in understanding how the products are made. The manufacturing process involves several precise steps:

a. Sourcing and Refining Nicotine

Pharmaceutical-grade nicotine—whether extracted from tobacco or synthesized—is the foundation of quality pouches. Its purity directly affects safety, consistency, and flavor stability.

b. Formulation and Blending

Manufacturers blend the nicotine with carriers like plant fibers and cellulose, then infuse it with flavorings. This stage enables custom nicotine strengths (2mg–12mg) and unique flavor profiles such as citrus, mint, or herbal blends.

c. Precision Filling and Packaging

Automated lines fill each pouch with exact quantities, maintaining consistency in weight and delivery. This precision is crucial for regulatory approval and consumer satisfaction.

d. Quality Assurance and Testing

Premium producers like Snuff Factory implement rigorous QA protocols, including chemical analysis, flavor profile testing, and pouch durability checks.

Buyers seeking transparency and consistent product quality should prioritize manufacturers with documented production standards and visible operations.

3. Brand, Origin, Equipment, and Technology Differences

Not all nicotine pouches are created equal. Beyond flavor and marketing, several factors set top brands and suppliers apart:

a. Brand Leadership

Well-known retail brands like ZYN (by Swedish Match) and VELO (by BAT) dominate global markets with wide distribution and strong brand equity. However, OEM manufacturers like Snuff Factory offer private-label versions of comparable quality—ideal for B2B buyers aiming to launch or scale their own lines.

b. Geographic Origin

Sweden and the USA remain benchmarks for quality and innovation. Increasingly, manufacturers in Asia—especially China—are gaining attention for scalable production and flexible customization.

c. Technology & Equipment

High-output facilities leverage robotic pouch-fillers, nitrogen-sealed packaging systems, and lab-based nicotine titration technologies. Manufacturers with modern infrastructure tend to deliver superior batch consistency and faster turnaround.

d. Certifications and Standards

Global buyers should prioritize suppliers with ISO certifications, GMP compliance, and third-party lab reports to avoid customs issues and ensure product safety in regulated markets.

4. How to Choose a Reliable Supplier (Featuring Echi Nicotine Bag Manufacturer)

Selecting the right nicotine pouch manufacturer is a strategic move. Whether you’re building a brand or expanding a distribution line, follow this supplier evaluation checklist:

a. Experience and Market Reputation

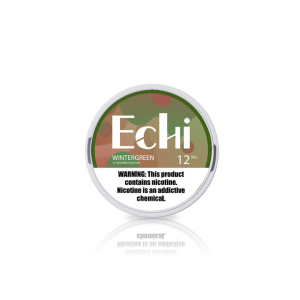

Partner with manufacturers like Echi, whose proven record in nicotine pouch production and white-label services ensures regulatory compliance and product scalability.

b. Capacity and Infrastructure

Confirm the supplier’s monthly output and production capabilities. For large-scale projects, inquire about lead times and automated lines that ensure efficiency without sacrificing quality.

c. Customization Options

From pouch size and nicotine strength to flavors and branded packaging, flexibility matters. Top-tier OEM partners like Snuff Factory support full-spectrum customization to match niche market needs.

d. Compliance and Documentation

Always request proof of compliance: SGS reports, MSDS sheets, ISO certifications, and regulatory clearance per market (e.g., FDA for the U.S., TPD for the EU).

e. Client Case Studies and Feedback

Ask for testimonials, bulk order histories, or co-branding case studies to verify supplier reliability. Transparency is a strong signal of a dependable partner.

Explore Echi’s capabilities or request samples at Get in Touch.

5. Final Suggestions

Navigating the global nicotine pouch landscape requires thoughtful supplier selection and brand positioning. Here are key takeaways for B2B buyers and developers:

-

For Market Entry: Leverage white-label partnerships for low-risk, fast deployment strategies.

-

For Brand Growth: Choose OEM partners who can scale production and offer packaging innovation.

-

For Global Reach: Work with manufacturers well-versed in international compliance to prevent delays or recalls.

-

For Differentiation: Invest in unique flavors, packaging, and nicotine strengths that align with your target demographic.

For tailored solutions and industry-leading support, explore Snuff Factory’s product catalog and production options.

In summary, the success of your nicotine pouch venture depends on aligning with skilled, transparent, and flexible manufacturers. By staying ahead of industry trends, leveraging white-label capabilities, and choosing partners like Echi, your brand can carve a competitive edge in the fast-evolving global market.

Ready to expand your portfolio? Visit Snuff Factory to explore custom manufacturing options and bring your nicotine pouch concept to life.

Leave a Reply

Want to join the discussion?Feel free to contribute!