Nicotine Pouches Brands: A Comprehensive Guide to Industry Trends, Manufacturing, and Supplier Selection

1. Industry Background and Trends

Nicotine pouches have quickly grown from niche products to global consumer staples, supported by heightened consumer demand for smoke-free alternatives and stricter tobacco regulations worldwide. The market for nicotine pouches, also known as nic bags, is projected to grow at a compound annual growth rate (CAGR) of 25% through 2028, driven by health-conscious consumers seeking discreet, convenient options to manage nicotine cravings.

Among the leaders in this category are major brands and OEM manufacturers who serve multinational distributors and retailers. Some brands focus on unique flavors and cultural appeal, while others prioritize technological innovation and compatibility with stringent regulatory requirements in markets such as Europe, North America, and Asia.

For buyers and suppliers, keeping pace with rapid market changes means investing in white-label nicotine bag solutions and forging partnerships with high-quality nicotine pouch manufacturers. These partnerships enable businesses to align product lines with evolving consumer demand and compliance standards.

2. Production Process of Nicotine Pouches

To understand what sets various nicotine bag brands apart, examining their production processes reveals key differentiators. The manufacturing process typically involves the following stages:

a. Sourcing and Refining Nicotine

Nicotine used in pouches is extracted and purified, often from tobacco leaves but increasingly from synthetic alternatives. Leading-edge facilities emphasize using pharmaceutical-grade nicotine to meet international quality benchmarks.

b. Formulation and Blending

The base nicotine mix is carefully combined with carriers like cellulose or plant fibers. This is the stage where brands can tailor flavors and nicotine concentrations to differentiate themselves, ranging from mint to fruity and more niche varieties.

c. Precision Filling and Packaging

State-of-the-art machinery ensures consistency in pouch size, weight, and nicotine content. Automation guarantees efficiency in mass production, while precision minimizes product variability—a key concern for distributors and consumers alike.

d. Quality Control

Nicotine pouch manufacturers such as Snuff Factory often adhere to strict quality control measures, ensuring their products pass chemical stability tests, weight verification, and sensory evaluations for flavor and texture.

For buyers seeking nicotine bag manufacturing process transparency, working with an experienced manufacturer is essential to meet end-user expectations. Exploring facilities and understanding production capabilities are highly recommended during the sourcing process.

3. Brand, Origin, Equipment, and Technology Differences

Several factors distinguish nicotine pouch brands apart from just flavors or marketing efforts. Buyers need to consider the geographic origin, the use of proprietary technology, and the equipment manufacturers employ.

a. Brand Leadership

While known nicotine pouch brands such as VELO or ZYN dominate global consumer markets, increasing opportunities exist for OEM partnerships with factories like Snuff Factory. These manufacturers allow international distributors to launch their own private-label products while leveraging proven production capabilities.

b. Geographic Origin

Sweden, the USA, and growing regions in Asia are traditionally popular hubs for high-quality nicotine manufacturing. Countries with tight regulatory frameworks often produce cleaner, safer products that appeal to health-conscious markets.

c. Production Technology

The availability of advanced equipment often determines consistency in pouch size, flavor dispersion, and nicotine concentration. Manufacturers such as Snuff Factory invest in cutting-edge, automated technologies to produce high-output, scalable batches for global clients.

d. Safety Standards and Certifications

Brands aligned with higher safety standards ensure greater market acceptance. Look for certifications such as ISO standards or GMP compliance when vetting suppliers.

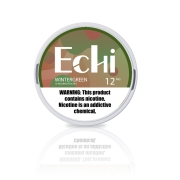

4. How to Choose a Reliable Supplier (Echi Nicotine Bag Manufacturer)

Selecting a reliable manufacturer for your nicotine pouch line is arguably the most critical decision in supply chain management. For OEM buyers and distributors, follow these steps to choose the right partner:

a. Evaluate Industry Expertise

Focus on companies with significant experience in nicotine bag manufacturing and white-label services like Snuff Factory. Their understanding of market dynamics and regulatory requirements can give your business a competitive edge.

b. Assess Production Capacity

Production scalability is vital for international buyers. Choose suppliers equipped with modern machines capable of meeting high-output requirements without sacrificing quality.

c. Request Regulatory Compliance Documentation

A dependable nicotine gum manufacturer or pouch producer should provide detailed certifications (e.g., ISO, SGS lab testing) to ensure their products align with international standards.

d. Inquire About Flavor and Packaging Flexibility

Buyers often prefer manufacturers offering customization options for flavors, pouch sizes, and packaging aesthetics.

e. Review Testimonials and Case Studies

Study customer reviews or request case studies of similar clients to gauge reliability and success metrics of the supplier. Companies like Snuff Factory provide transparency, enabling buyers to make informed decisions about their investment.

For more information, consider connecting with a reputable nicotine bag manufacturer like Snuff Factory directly (Get in Touch) to explore their production capabilities.

5. Final Suggestions

For international buyers, distributors, and OEM customers, navigating the nicotine pouch market requires due diligence when choosing brands and suppliers. Whether you’re interested in sourcing top-tier products or launching your own white-label nicotine bag, consider these recommendations:

-

Partner with Proven Manufacturers: Focus on suppliers with a track record of scalable production and product quality, such as Snuff Factory, who specialize in customized and bulk solutions across nicotine formats (Explore Products).

-

Invest in Unique Branding: While flavors and marketing are important, differentiating your product in packaging and target market alignment will set you apart in competitive markets.

-

Keep an Eye on Evolving Trends: Vigilantly monitor shifts in regulation, consumer preferences, and competitive activities to maintain an edge in the nicotine industry.

By aligning your sourcing strategy with experienced suppliers, you can ensure greater success in penetrating this growing market. Whether you’re shipping to retail stores, distributing wholesale, or building an OEM pipeline, the right partnerships make all the difference for long-term growth.

Leave a Reply

Want to join the discussion?Feel free to contribute!