How to Open a Nicotine Pouch Box: An Operation Guide for B2B Buyers and End-Users

Nicotine pouches have surged in popularity as consumers increasingly seek smoke-free, spit-free alternatives to traditional tobacco and vaping. While the product itself is widely discussed, less attention is paid to a critical part of the supply chain: how to properly open a nicotine pouch box. For B2B buyers, distributors, and retailers managing inventory, understanding the nuances of box designs and handling practices can help preserve product integrity, reduce loss, and elevate customer satisfaction.

This practical guide walks you through the essentials—from identifying box types to safely accessing their contents—so you can handle both retail-ready units and bulk shipments with confidence.

1. Recognizing the Structure of Nicotine Pouch Boxes

Nicotine pouch packaging is engineered around three key principles: protection, ease of use, and branding impact.

-

Protection: Nicotine pouches are sensitive to moisture, air, and physical pressure. That’s why most manufacturers use rigid cardboard or coated materials, sometimes with tamper-evident or resealable features, to ensure freshness and prevent contamination.

-

Ease of Handling: Pouch boxes typically incorporate user-friendly features like perforated tear lines, fold-open flaps, or snap tabs. These designs help end-users, store staff, and logistics teams quickly access products without damaging them.

-

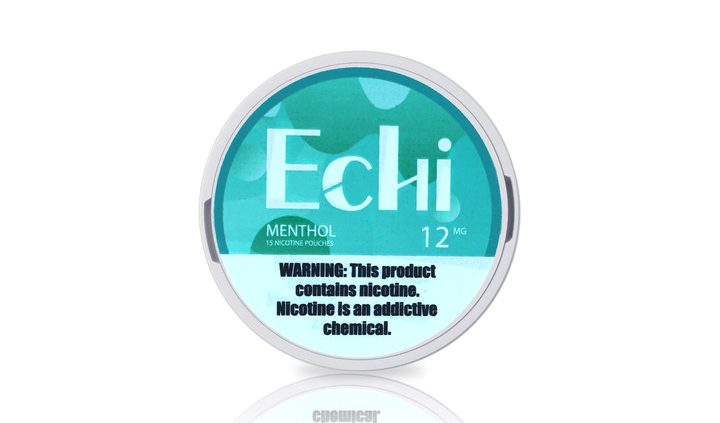

Brand Presentation: Whether sold in stores or shipped in bulk, the pouch box serves as a brand ambassador. From color schemes to compliance labeling, every element is designed to attract consumers and maintain regulatory standards.

Common Box Types in the Industry:

-

Retail-Ready Packs: Compact units containing 1–5 tins, designed for direct consumer use.

-

Bulk Shipment Boxes: Larger cartons holding multiple retail packs, often used by distributors and wholesalers.

-

Display Cases: Pre-designed to sit directly on retail shelves or counters, typically with built-in tear-away sections for easy product access.

Understanding these formats can help buyers—from convenience store chains to private-label brands—make smarter sourcing decisions when evaluating offers from nicotine factories or white-label nicotine manufacturers.

2. Step-by-Step: How to Open a Nicotine Pouch Box Properly

Efficient handling starts with recognizing the box’s design and applying appropriate methods. Here’s a step-by-step approach for opening different pouch box types safely and effectively:

Step 1: Inspect the Box Design

Before opening, examine the box for clear indications of its opening mechanism:

-

Perforated lines or arrows may signal pull-tabs.

-

Factory-sealed seams often indicate bulk shipping units.

-

Display-ready flaps are usually marked for tear-away access.

Step 2: Prepare the Right Tools (If Necessary)

If there are no easy-open features, equip yourself with a box cutter or utility knife. Always slice along the taped seams or pre-cut edges rather than forcing the box open, which can crush or tear internal contents.

Step 3: Open Gently and Cleanly

-

For retail packs, a finger pull is often sufficient.

-

For bulk boxes, cut along the tape or fold seams. Avoid applying pressure on the center or sides, which could damage the tins or pouches inside.

Step 4: Check for Damage

Once opened, inspect the inner packaging. Look for signs of moisture exposure, seal breaches, or physical crushing. Not only does this ensure quality for your customers, but it also helps in documenting claims with your nicotine pouch supplier if needed.

Step 5: Store Appropriately

After opening:

-

Keep pouches in a dry, cool space, away from direct sunlight.

-

If redistributing to retail points, re-pack with care to prevent slippage or exposure.

Many nicotine manufacturers now offer display-ready packaging, which simplifies both retail logistics and visual merchandising. For example, you can explore shelf-ready solutions at Snuff Factory.

3. Why Proper Box Handling Matters for Businesses

For B2B buyers, how you open and handle nicotine pouch boxes can directly affect both operations and profitability. Here’s why careful handling is more than just good practice:

-

Minimizes Product Loss: Mishandled packaging can puncture or contaminate pouches, leading to write-offs.

-

Supports Regulatory Compliance: Many packages carry usage and safety warnings. Preserving these helps retailers maintain labeling compliance.

-

Preserves Brand Appearance: Damaged or repackaged units often undermine product presentation, which impacts the consumer’s first impression and repeat sales potential.

From nicotine distributors managing pallets to retailers restocking shelves, handling methods can influence overall product performance and consumer satisfaction.

4. Packaging Trends That B2B Buyers Should Monitor

The packaging landscape for nicotine pouches is evolving to meet both environmental and market demands. Here are innovations gaining traction:

-

Eco-Friendly Materials: More brands now use recyclable or biodegradable cardboard while maintaining strength and moisture resistance.

-

Tamper-Evident Designs: Features like perforated seals or breakaway tabs protect product integrity and improve consumer trust.

-

Interactive Packaging: Smart boxes with QR codes enable verification, traceability, or promotional engagement at the point of use.

If you’re sourcing from a nicotine pouch manufacturer for OEM or private label production, incorporating such features can set your offering apart. Brands like Snuff Factory lead with innovation by offering packaging tailored to market demands and logistics efficiency.

5. Frequently Asked Questions (FAQ)

Q1: What materials are commonly used in pouch boxes?

Most are made from rigid cardboard with moisture barriers. Bulk boxes might also include plastic liners or insulation for long-haul transport.

Q2: Are nicotine pouch boxes recyclable?

In many cases, yes—especially with eco-focused packaging. Always check for recycling labels or material indicators.

Q3: Can I reuse bulk shipment boxes?

Yes, as long as the structural integrity is maintained. Damaged boxes, however, can compromise the freshness and safety of the pouches.

Q4: Why do box sizes vary between manufacturers?

Box sizes are typically determined by the intended use case—smaller boxes for consumer purchase, larger cartons for wholesale storage and transportation.

Still unsure about custom packaging needs? Reach out to Snuff Factory for detailed consultations.

Conclusion

Opening a nicotine pouch box might appear to be a basic task, but it’s a key part of maintaining quality across the supply chain—from factory to consumer. For buyers and sellers alike, understanding box design, using proper tools, and following correct handling procedures can minimize waste, enhance safety, and protect your brand image.

As the nicotine pouch industry matures, packaging continues to evolve—not just in how it looks, but in how it functions. Whether you’re managing high-volume inventory or launching a new white-label product, mastering these fundamentals will give you a competitive edge.

Looking to streamline your nicotine pouch operations? Discover high-performance packaging solutions at Snuff Factory.

Leave a Reply

Want to join the discussion?Feel free to contribute!