How Many Pouches Are in Grinds? A Comprehensive Guide for Industry Stakeholders

As consumer interest in tobacco-free alternatives continues to rise, oral pouch products—ranging from nicotine pouches to caffeine-based innovations like Grinds—have carved out a distinct niche in the wellness and performance sectors. Among the questions frequently asked by distributors, OEM clients, and B2B buyers is a simple yet fundamental one: how many pouches are in a can of Grinds?

This article answers that question in detail while offering broader insights into product manufacturing, supply chain differentiation, and how companies can capitalize on the oral pouch category from both a product and brand development standpoint.

1. Industry Background and Trends

Grinds coffee pouches are part of a rapidly growing segment within the functional consumer goods space. Originally marketed as a tobacco alternative for dip users, Grinds now appeals to a wider demographic—from college students to working professionals—who seek clean energy without smoking, chewing, or drinking.

According to global industry data, the oral pouch market (which includes nicotine, caffeine, and botanical ingredients) is experiencing double-digit annual growth. Consumer demand is driven by convenience, discretion, and lifestyle alignment.

At the same time, there’s a parallel trend toward white label nicotine pouch solutions and customizable product lines. Manufacturers that traditionally produced nicotine pouches are now diversifying into caffeine and other active ingredient categories, offering businesses the flexibility to co-develop and scale functional pouch products across multiple sectors.

2. How Grinds Are Made: Production Process Insights

The production process behind Grinds mirrors that of nicotine bag manufacturing, making the transition between these product types feasible for OEM clients. Here’s a high-level overview:

Ingredient Blending and Optimization

Grinds pouches use food-grade coffee grounds as a base, combined with natural or artificial flavorings, stabilizers, and optional functional additives like B-vitamins. The formulation process focuses on uniform texture, taste, and caffeine distribution. In nicotine pouch production, this phase would involve nicotine in salt, liquid, or powder form.

Pouch Filling and Sealing

After formulation, precise quantities are portioned into food-safe cellulose pouches using automated machinery. These pouches are then heat-sealed and prepared for canning. The filling process is closely regulated to ensure consistency in strength, flavor release, and pouch weight.

Packaging: How Many Pouches Are in Grinds?

Each Grinds can contains approximately 18 to 20 pouches, depending on the flavor and moisture content. This count is considered standard across most SKUs. These round tins are designed for on-the-go convenience and help consumers manage their intake per use session.

For nicotine pouches, quantities vary by market—some regions offer 15, 20, or even 30 pouches per can depending on legal requirements or consumer preference.

3. Differentiation by Brand, Origin, and Technology

In a competitive and fast-moving market, understanding what separates one pouch product from another can help brands make smarter sourcing decisions. Here are the key differentiators:

Flavor Innovation

Grinds specializes in coffee-inspired and dessert-style flavors—ranging from Mocha and Cinnamon Roll to Vanilla and Peppermint. By contrast, nicotine pouch brands often focus on mint, citrus, or fruity profiles. Manufacturers like Snuff Factory offer flavor development services tailored for either market.

Manufacturing Technology and Scalability

Whether producing caffeine or nicotine pouches, manufacturers typically use similar high-speed pouching equipment, adapted for ingredient-specific needs. State-of-the-art lines feature moisture calibration, automated weighing, and hygienic sealing systems. Suppliers such as Snuff Factory leverage this equipment to deliver scalable, consistent results across SKUs.

Origin and Regulatory Reputation

Products manufactured in countries with strict quality control—such as Sweden for nicotine or the U.S. for caffeine—tend to enjoy stronger brand perception and easier market access. Understanding your supplier’s regional capabilities can impact your ability to comply with local regulations.

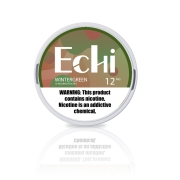

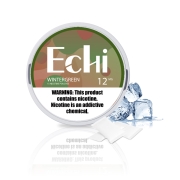

4. How to Choose a Reliable Supplier (Featuring Echi and Snuff Factory)

Whether you’re entering the caffeine pouch market or scaling a nicotine pouch portfolio, your manufacturing partner is key to long-term success. Here’s what to look for:

Expertise Across Product Categories

A top-tier partner should demonstrate mastery in both caffeine and nicotine pouch production. Manufacturers like Snuff Factory and Echi offer cross-functional knowledge and can help you bridge both product lines for a more diverse offering.

White Label & OEM Flexibility

Look for partners that support white label nicotine bags and functional pouch customization. This includes adjustable flavor profiles, nicotine or caffeine strengths, pouch sizes, and packaging formats—critical for building a recognizable brand presence.

High Output & Reliable Fulfillment

Ensure your manufacturer can meet large-volume orders and adapt to demand fluctuations without compromising quality. Ask about MOQs, production capacity, and batch testing procedures.

Global Compliance and Certification

Your partner should offer transparency about ISO, GMP, or FDA-related certifications. Their experience with international labeling laws and ingredient safety ensures smoother entry into regulated markets.

Get started with supplier inquiries via the Get in Touch page.

5. Final Takeaways for Stakeholders

Grinds pouches—and the wider caffeine pouch category—present a strong opportunity for product innovation and revenue diversification. Whether you’re a B2B buyer, distributor, or brand incubator, here’s what to keep in mind:

-

Standard Count: Grinds typically contain 18–20 pouches per can.

-

Crossover Manufacturing: The same expertise and equipment used for nicotine bags can be applied to caffeine pouches, making OEM expansion easier.

-

Strategic Partnerships: Choosing a reliable manufacturer like Snuff Factory or Echi helps streamline development and ensures quality compliance.

-

Portfolio Expansion: Start with caffeine, expand into nicotine—or vice versa—to meet evolving market demand.

Ready to Explore the Pouch Market?

Whether you’re building a functional wellness brand or entering the nicotine alternative segment, understanding the mechanics behind products like Grinds is a great place to start. With reliable partners and a clear grasp of product architecture, your brand can thrive in this next-generation product category.

Learn more about scalable pouch manufacturing at SnuffFactory.com

Leave a Reply

Want to join the discussion?Feel free to contribute!