Guide to Procuring Tobacco Powder for Corporate Use: Key Insights for Bulk Buyers

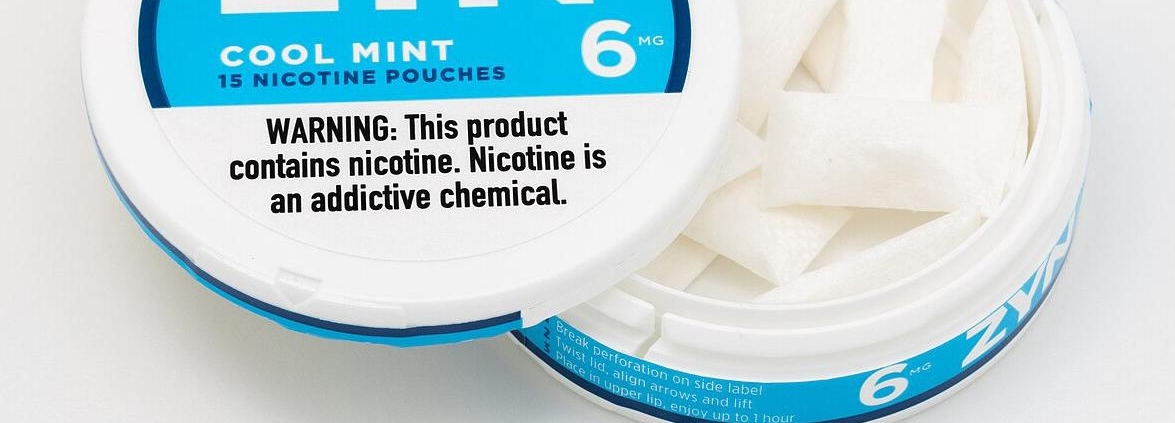

Tobacco powder, a finely milled derivative of tobacco leaf, has become a core ingredient across multiple commercial applications—from smokeless oral products to nicotine extraction and even agricultural research. As the demand for high-quality tobacco powder grows, so too does the need for strategic, cost-effective sourcing solutions tailored to bulk buyers.

Whether you’re a consumer goods manufacturer, a liquid nicotine supplier, or a white-label brand entering the smokeless category, understanding the procurement process is key to operational success. This guide offers a comprehensive overview of how to source tobacco powder efficiently and compliantly, while maximizing value through customized supply partnerships.

1. Selecting the Right Tobacco Powder for Your Business Use

Corporate buyers must be highly selective when sourcing tobacco powder, as quality directly affects product performance, regulatory compliance, and consumer satisfaction.

Key Specifications to Consider:

-

Grade & Purity: Industrial-grade tobacco powder is common in nicotine extraction or agricultural use, while premium-grade versions are ideal for high-end oral products like dry or moist snuff.

-

Processing Method: Look for specifications such as mesh size, moisture levels, and curing techniques (air-cured, fire-cured, etc.), all of which impact flavor profile and extraction efficacy.

-

Intended Applications:

-

Oral tobacco products (e.g., dry snuff, moist snuff)

-

Raw material for nicotine extraction in vaping or pharmaceutical applications

-

R&D use in agricultural or biological studies

-

For best results, partner with a specialized nicotine manufacturer that understands these variables and can ensure consistent supply aligned with your downstream production needs. Snuff Factory offers several tobacco powder variants optimized for corporate use.

2. Navigating Regional Procurement Channels

Your sourcing region will significantly influence cost, quality, and regulatory burden.

United States:

The U.S. is home to premium tobacco farms and high-quality processing facilities, especially in the Southeast. Procurement here typically emphasizes FDA-compliant manufacturing and strong documentation. However, lead times and costs may be higher compared to offshore options.

China:

China provides competitively priced tobacco powder at industrial scale. While costs are favorable, it’s crucial to verify ISO and GMP certifications to meet import regulations in Western markets. For large-volume orders, Chinese factories often support OEM arrangements with custom particle size and packaging options.

Europe:

European suppliers focus on organic certifications and sustainable farming practices. Buyers targeting clean-label or eco-conscious products often favor EU sourcing despite higher price points. Note that tobacco-related imports may be subject to strict oversight under the EU Tobacco Products Directive.

When working across regions, it’s beneficial to establish a relationship with a global-facing supplier like Snuff Factory who can help you navigate compliance across borders.

3. Understanding the Cost Structure

A clear understanding of cost elements will help you assess supplier quotes and optimize your budget.

Main Cost Drivers:

-

Raw Material Quality: High-grade leaf material demands higher pricing but ensures consistent outcomes for finished products.

-

Manufacturing Technology: Advanced grinding, drying, and sieving equipment raise costs but improve product consistency and purity.

-

Customization & White Labeling: Tailored blends, flavor additions, or packaging formats can affect unit cost—particularly for OEM projects.

-

Logistics: International freight, bulk handling, and storage conditions (e.g., humidity control) contribute significantly to final pricing.

To maintain cost control, negotiate long-term agreements and explore bulk tobacco powder options through trusted suppliers like Snuff Factory, who offer economies of scale and custom packaging.

4. Choosing Between White Label and OEM Supply Models

Your go-to-market strategy will influence how you engage with suppliers.

White Label Model:

Ideal for businesses aiming to quickly enter the smokeless market. The supplier provides finished or semi-finished products, which you brand and sell as your own. This reduces development time and investment.

OEM Model (Original Equipment Manufacturer):

Best for companies seeking full control over formulation, ingredient sourcing, and branding. OEM partners co-develop a custom tobacco powder solution tailored to your product line—ideal for nicotine patch manufacturers, e-liquid formulators, or specialized research applications.

If customization is a priority, consider an OEM partner like Snuff Factory, which supports bespoke formulations, granulation levels, and nicotine content adjustments.

5. Steps to Place Orders and Start Partnerships

Ensuring quality and smooth fulfillment involves a few essential steps:

Step 1: Define Your Requirements

Specify parameters such as:

-

Target use (oral, extraction, R&D)

-

Particle size or mesh standard

-

Required certifications (FDA, ISO, etc.)

-

Packaging (bulk sacks, resealable bags, etc.)

Step 2: Request Samples

Test product quality and compatibility with your manufacturing systems. Reputable suppliers like Snuff Factory typically accommodate small sample orders.

Step 3: Assess Supplier Capability

-

Review production capacity and scalability

-

Ask for documentation and audit trails

-

Check client reviews or request references

Step 4: Negotiate Pricing and Fulfillment Terms

Discuss volume-based discounts, payment terms, and logistics options. For OEM projects, request a detailed quote based on custom specs.

Step 5: Place Your Order

Finalize your PO and initiate production. Advanced suppliers will provide real-time order tracking, QA documentation, and after-sales support.

6. Key Terms and Supplier References

Here’s a quick glossary of industry-relevant terms and links to helpful resources:

-

Tobacco Factory – A processing facility that prepares and packages commercial-grade tobacco powder.

-

Liquid Nicotine Wholesaler – Entities that buy tobacco powder for refining into nicotine concentrates.

-

Nicotine Preparation Method – The technique used to extract and purify nicotine from tobacco powder.

-

Nicotine Patch Manufacturer – OEM clients who utilize pharmaceutical-grade powder for therapeutic products.

-

Snuff Factory – A global supplier offering white-label and OEM tobacco powder for industrial applications. Explore Products | Request a Quote

Final Thoughts: Building Smarter Procurement Strategies

Sourcing tobacco powder at scale demands more than a purchase order—it requires a strategic approach rooted in supplier vetting, quality control, and an understanding of your production goals. By following the steps in this guide, buyers can confidently enter long-term, profitable partnerships while mitigating supply chain risks.

For customized support, sample requests, or white-label inquiries, connect with Snuff Factory—your expert partner in the tobacco supply chain.

Leave a Reply

Want to join the discussion?Feel free to contribute!