Different Flavors of Dip: A Comprehensive Guide for Buyers, Distributors, and OEM Customers

Industry Background and Trends

The global nicotine product market has evolved significantly over the past decade, with flavored dips emerging as a key growth segment. Driven by increasing demand for smoking alternatives and advancements in product formulation, flavored dips have gained traction among consumers seeking both variety and a more refined nicotine experience.

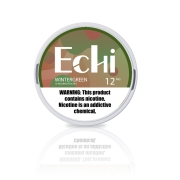

While traditional flavors like mint and wintergreen remain staples, the market has expanded to include fruit, spice, and dessert-inspired profiles—each tailored to regional and generational preferences. This trend is especially evident in North America and Europe, where premium branding and flavor sophistication play an increasingly vital role in product differentiation.

For buyers, distributors, and OEM clients, staying attuned to these flavor trends and understanding their role in consumer choice is essential when selecting a product line or manufacturing partner.

The Production Process of Flavored Dips

Creating a consistent and high-quality flavored dip involves a carefully controlled manufacturing process. From raw ingredient sourcing to final packaging, each step is designed to preserve flavor integrity and ensure consumer safety.

-

Raw Material Procurement

The process begins with selecting high-grade nicotine—either tobacco-derived or synthetic. The quality and purity of this base significantly influence both the flavor and the user experience. -

Flavor Development

Flavoring compounds, whether natural extracts or artificial blends, are designed in collaboration with food scientists to match consumer expectations. Cherry, coffee, bourbon, and citrus are common profiles, often fine-tuned with stabilizers to ensure long-lasting taste. -

Mixing and Blending

Uniformity is critical. Industrial-grade mixers integrate flavors into the nicotine base, ensuring that every can of dip offers a consistent sensory experience. High-end manufacturers rely on automated systems to maintain quality across large production runs. -

Packaging

To retain freshness and flavor, dips are packaged in sealed containers using vacuum or nitrogen-flush systems. For brands leveraging white label nicotine bag solutions, this stage also includes customizable branding and design.

A trusted nicotine dip or nicotine gum manufacturer will also implement quality checks at every stage—especially for flavored products, where consistency can make or break brand credibility.

Brand, Origin, Equipment, or Technology Differences

The flavored dip market is characterized by fierce competition and fast-paced innovation. Manufacturers differentiate themselves through a mix of regional strengths, technical expertise, and investment in flavor-forward technologies.

-

Flavor Leadership by Region

North American brands often take risks with bold, unconventional flavors like whiskey, caramel, or cinnamon spice. In contrast, European producers focus on heritage and purity, favoring menthol, eucalyptus, or organic mint with ethically sourced ingredients. -

Advanced Manufacturing Equipment

Leading manufacturers invest in high-precision equipment to automate blending, portioning, and packaging. This enhances scalability while ensuring that flavor profiles are uniformly distributed across batches. -

Technology in Quality Assurance

Some manufacturers incorporate machine learning or AI-driven sensors to detect inconsistencies in flavor composition or moisture content—ensuring top-tier quality for every can produced. -

Origin and Certification

The geographical origin of the nicotine and flavoring ingredients—combined with certifications for organic, sustainable, or clean-label practices—can heavily influence consumer perception and market positioning.

How to Choose a Reliable Supplier (Echi Nicotine Bag Manufacturer)

For distributors and OEM customers seeking flavored dips, supplier reliability is paramount. Here’s how to evaluate potential partners effectively:

-

Proven Manufacturing Experience

Look for manufacturers with specialized knowledge in nicotine bag manufacturing, particularly those offering a wide flavor catalog. Companies like Snuff Factory are experienced in producing customized, scalable solutions. -

Customizable and Scalable Solutions

A capable white label nicotine bag supplier will allow buyers to tailor flavors, nicotine strength, and packaging—ideal for market testing or launching a proprietary product line. -

Regulatory Compliance and Certifications

Ensure the supplier meets local and international standards, such as FDA, GMP, or EU regulations. This is crucial not only for product safety but also for long-term brand credibility. -

Comprehensive Customer Support

Leading suppliers offer support services including R&D collaboration, custom flavor trials, and branding consultations. For example, Snuff Factory supports its clients throughout the entire product development and order fulfillment process.

Final Suggestions

In the fast-growing flavored dip market, the right manufacturing partner is the key to success. Buyers, distributors, and OEM customers should seek out suppliers that combine technical expertise with a creative approach to flavor development.

Evaluate your options based on production capabilities, regulatory track record, and flavor innovation. Leverage white label or OEM solutions to offer unique, market-responsive products without building infrastructure from scratch.

Flavored dips will continue to evolve—with new combinations like caffeine-infused pouches, herbal blends, and dual-flavor formats gaining traction. By staying ahead of trends and working with reliable partners like Snuff Factory, businesses can effectively capture consumer interest and build a resilient, flavor-rich product portfolio.

Leave a Reply

Want to join the discussion?Feel free to contribute!