Bulk Purchasing of Nicotine Products

This comprehensive guide aims to assist corporate buyers in the bulk procurement of nicotine products. It covers key aspects including sourcing channels, cost components, differences between white label and OEM products, and the standard ordering and sample cooperation process. Throughout this guide, terms like nicotine preparation method, liquid nicotine wholesaler, nicotine manufacturer, nicotine patch manufacturer, and nicotine factory will be referenced, with links to relevant resources for further exploration.

1.Understanding the Various Channels for Purchasing Nicotine Products

A. China

China serves as one of the largest global hubs for nicotine product manufacturing. The country hosts numerous nicotine factories and liquid nicotine wholesalers, supported by efficient B2B platforms that enable direct manufacturer purchases, often at competitive pricing.

B. United States

In the U.S., bulk nicotine procurement is available via domestic wholesalers or through direct engagement with international manufacturers. U.S.-based wholesalers often provide streamlined logistics and regulatory compliance advantages for local buyers.

2.Breakdown of Costs in Bulk Nicotine Products Procurement

When planning nicotine product procurement, understanding the cost structure is vital. The primary cost elements include:

A. Equipment

Machinery for nicotine extraction, processing, and packaging constitutes a significant investment and influences production efficiency and product quality.

B. Raw Materials

The raw materials involve either tobacco leaves or synthetic nicotine sources, representing a substantial portion of the overall cost.

C. Processes

This encompasses all operational procedures such as extraction, purification, formulation, and packaging, which are essential to meet product standards and regulatory requirements.

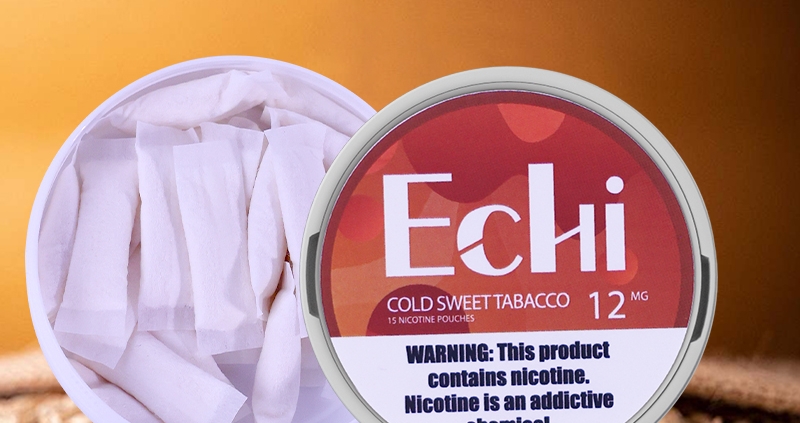

3.Comparing White Label and OEM

A. Definition of White Label and OEM

-

White Label: Products manufactured by one company to be rebranded and sold under another company’s brand name.

-

OEM (Original Equipment Manufacturer): Products designed and produced by the original company, often with more proprietary control over specifications.

B. Differences between White Label and OEM

White label offers greater flexibility in branding, packaging, and pricing, ideal for faster market entry and brand visibility. OEM products typically provide higher control over product quality and manufacturing standards but may limit branding freedom.

C. Selection Suggestions

Choosing between white label and OEM should align with your business goals:

-

Opt for white label if you prioritize rapid market penetration and flexible branding.

-

Consider OEM if product customization and quality control outweigh branding concerns.

4.Ordering and Sample Cooperation Process

Most nicotine product suppliers maintain organized ordering systems. It is common practice to request product samples before committing to large orders to verify quality and compatibility. To initiate sample requests or obtain quotes, use the supplier’s official contact channels, such as the Snuff Factory’s get in touch page.

Bulk purchasing of nicotine products requires a holistic understanding beyond product specifications. Awareness of procurement channels, cost structures, and product sourcing models (white label vs. OEM) is critical for making informed decisions. Equally important is selecting suppliers with straightforward, secure ordering processes to facilitate smooth business operations.

For a broad selection of nicotine products, visit Snuff Factory’s product catalog.

Leave a Reply

Want to join the discussion?Feel free to contribute!