Bulk Nicotine Purchasing: What Every Corporate Buyer Should Know

As the demand for vaping and nicotine-based products continues to expand across global markets, more businesses are seeking ways to streamline their sourcing strategies. If you’re exploring how to secure high-quality nicotine in large quantities—whether for manufacturing, repackaging, or product development—this guide walks you through everything you need to consider.

Let’s break down the options, decisions, and steps that will help you move from inquiry to delivery with clarity and confidence.

Forms of Nicotine: Choosing the Right Type for Your Needs

Not all nicotine products are created equal. Depending on your product line and compliance requirements, your business may need liquid nicotine, nicotine salts, or even transdermal formats such as nicotine patches. Each variation comes with its own preparation method, purity standards, and regulatory implications.

For instance, nicotine intended for e-liquids often comes as USP-grade liquid nicotine, while a nicotine patch manufacturer may require stabilized formulations suitable for pharmaceutical use. Choosing the right nicotine preparation method depends heavily on your intended application and your customers’ expectations.

Thinking in Bulk? Here’s What to Consider

Before you approach a liquid nicotine wholesaler or nicotine factory, ask yourself a few essential questions:

- Do you have the right storage facilities for large volumes of regulated substances?

- Is your supply chain equipped to handle time-sensitive or temperature-sensitive deliveries?

- What’s your minimum viable order to ensure profitability?

Pricing in the nicotine space is sensitive to volume, contract length, and even region of origin. If you’re dealing with a nicotine patch manufacturer or exploring private label options for nicotine pouches, make sure your logistics, demand forecasts, and compliance paperwork are already in place.

Geography plays a key role in cost, compliance, and production timelines. Here’s how the two major sourcing regions compare:

China

Known for its robust manufacturing infrastructure, China is a major player in nicotine production. Many white label nicotine bag producers and OEM suppliers operate here, offering scalable solutions and competitive pricing. However, navigating documentation and shipping logistics—especially around regulated compounds—requires strong vendor relationships and clear quality control processes.

United States

American suppliers typically operate under stricter FDA and DEA oversight, which can enhance trust and traceability. The market here favors both boutique-scale partnerships and industrial-grade OEM operations. If regulatory compliance is a top priority, working with a domestic nicotine manufacturer may offer more transparency and flexibility.

Understanding Your Cost Structure

Nicotine pricing is rarely just about the raw material. It’s essential to understand the three key cost drivers:

- Equipment: For OEM nicotine bag production, upfront tooling or capsule filling machines can affect per-unit cost.

- Raw Materials: The type and grade of nicotine used—whether synthetic, tobacco-derived, or pharma-grade—will influence pricing.

- Processes: Filtration, stabilization, blending, and packaging all add to the final cost.

If you’re considering transitioning to a white label nicotine bag supplier, request full breakdowns so you can plan your margins accordingly.

White Label vs. OEM: Which Is Right for You?

The right production model depends on how much control you want over your brand, formulation, and packaging.

- White Label: Perfect for businesses looking to enter the market quickly with ready-to-go formulations. Many white label nicotine bag suppliers offer customization on packaging and minor flavor adjustments.

- OEM (Original Equipment Manufacturer): Ideal for companies wanting to build proprietary products from scratch. You control formulation, flavor, pouch size, and even ingredient sourcing.

If you’re unsure, start with a white label nicotine bag program and scale into OEM production as your customer base grows.

Ready to Place an Order? Here’s What Happens Next

Once you’ve selected your supplier, the next steps are fairly straightforward:

- Request a Sample: Always test a small batch before full production. This helps ensure product quality and gives you a chance to refine your request.

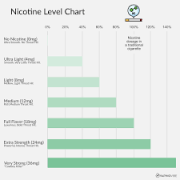

- Confirm Your Specs: Detail nicotine strength, format, packaging type, and labeling requirements.

- Negotiate Terms: Discuss MOQs (minimum order quantities), payment structures, and shipping schedules.

- Kick Off Production: After signing off on samples and terms, your production slot will be booked and raw materials sourced.

Need Help Getting Started?

Whether you’re a startup launching a new product line or an established brand seeking a better supply partner, we’re here to help. Get in touch to explore OEM nicotine bag manufacturing or white label nicotine pouch services tailored to your business.

Let’s make your nicotine supply chain smoother, safer, and more scalable.

Leave a Reply

Want to join the discussion?Feel free to contribute!