A Comprehensive Guide to Bulk Purchasing Empty Dip Pouches: Key Insights for Corporate Buyers

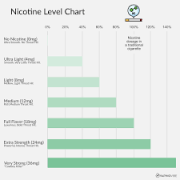

Empty dip pouches are a fundamental component in the nicotine industry, primarily used in smokeless tobacco products such as snus and dipping tobacco. These pouches serve as the vessel for finely shredded tobacco or nicotine blends, enabling controlled and convenient consumption. For manufacturers, selecting and sourcing high-quality empty dip pouches is critical as it directly impacts product performance, consumer satisfaction, and brand reputation.

With the growing demand for smokeless alternatives, bulk procurement of empty dip pouches has become a strategic priority for both emerging and established nicotine product manufacturers. This guide outlines essential considerations and best practices to help corporate buyers source dip pouches efficiently and cost-effectively.

How to Purchase Empty Dip Pouches in Bulk

When purchasing dip pouches in bulk, it is important to clearly define your product requirements to ensure optimal compatibility and quality:

-

Material Specifications

Dip pouches are typically manufactured from materials including paper, biodegradable fibers, or synthetic textiles. Selecting the appropriate pouch material is vital, especially when targeting premium or environmentally conscious consumer segments. -

Size and Customization

Pouch dimensions vary according to user preference and product positioning—from smaller, discreet pouches to larger formats intended for longer-lasting use. Engage with suppliers to customize pouch size and design to your specifications. -

Product Compatibility

Confirm that the pouch material and construction are suitable for the intended filling, whether it is liquid nicotine, tobacco cut, or a proprietary blend. -

Supplier Accreditation

Partner with manufacturers certified under international quality standards (e.g., ISO 9001) to guarantee consistent quality and regulatory compliance.

Trusted suppliers such as Snuff Factory offer a wide range of customizable solutions tailored to nicotine manufacturers’ needs.

Differences in Procurement Channels Across Regions

Geographic location significantly affects supplier options, regulatory requirements, and logistics:

China

-

Advantages: Competitive pricing, high production capacity, and access to cutting-edge manufacturing technologies.

-

Challenges: Potential regulatory complexities and longer shipping times due to import/export restrictions.

United States

-

Advantages: Quicker delivery times, ease of communication, and adherence to rigorous regulatory frameworks (e.g., FDA compliance).

-

Challenges: Typically higher manufacturing costs compared to overseas alternatives.

Companies operating internationally benefit from leveraging suppliers experienced in cross-border logistics and regulatory navigation, such as Snuff Factory.

Cost Composition

Understanding the cost drivers in bulk pouch procurement is essential for budgeting and optimizing expenses:

-

Raw Materials: Quality and eco-friendly materials incur higher costs but enhance product value.

-

Manufacturing: Advanced machinery ensures precision but may increase unit costs.

-

Shipping & Customs: International freight, customs duties, and taxes must be factored into total landed cost.

-

Warehousing: Bulk inventory storage requires suitable facilities to maintain product integrity.

-

Customization Fees: Branding, logo imprinting, or unique pouch features may attract additional charges but improve market differentiation.

White Label vs. OEM Production: Making the Right Choice

White-Label Production

Involves purchasing generic, ready-made dip pouches without customization. This model suits startups or small enterprises seeking low-cost entry and rapid product deployment.

Benefits:

-

Lower upfront costs

-

Fast turnaround

-

Minimal operational complexity

OEM Production

OEM refers to fully customized pouch manufacturing tailored to brand specifications, allowing for unique designs, sizes, and materials. Best suited for established companies aiming for brand differentiation.

Benefits:

-

Complete control over product attributes

-

Stronger brand identity

-

Enhanced consumer appeal

Your choice should align with your company’s scale, budget, and long-term brand strategy. OEM services with comprehensive customization are available at Snuff Factory.

Submitting Orders, Requesting Samples, and Onboarding Suppliers

To ensure a smooth procurement experience, follow these essential steps:

-

Inquiry Submission

Initiate communication through formal channels—online forms or direct contact. Reliable manufacturers like Snuff Factory streamline this process. -

Sample Evaluation

Request samples to verify material quality, pouch construction, and dimensional accuracy before committing to bulk orders. -

Order Confirmation

Finalize order details including quantity, customization, delivery timelines, and payment terms. -

Production Oversight

Maintain communication during production cycles to monitor quality and resolve any issues promptly. -

Establish Long-Term Partnership

Cultivate ongoing relationships for supply chain stability, volume discounts, and priority service.

Conclusion

Bulk purchasing empty dip pouches is a strategic cornerstone for nicotine product manufacturers seeking scalability and quality. By carefully selecting suppliers, understanding cost structures, and choosing the appropriate production model, businesses can optimize their operations and product appeal.

Whether entering the market or expanding an existing portfolio, partnering with reputable manufacturers like Snuff Factory provides access to high-quality, customizable dip pouch solutions that support sustainable growth.

Take action now by contacting trusted suppliers and securing the best pouch products to elevate your nicotine brand.

Leave a Reply

Want to join the discussion?Feel free to contribute!